PP PE HDPE LDPE LLDPE Film Agriculture Waste Irrigation Pipe Net Greenhouse Mulch Film Washing Recycling Line

Description

Basic Info

| Model NO. | RTWWT |

| Plastic Type | HDPE LDPE LLDPE PP Film |

| Screw | 0 |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| Color | Could Be Customized |

| After-Sale Service | Engineers Available to Service Machinery Overseas |

| Transport Package | Wrap Film |

| Specification | TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 300~3000kg/H |

Packaging & Delivery

Package size per unit product 4200.00cm * 600.00cm * 500.00cm Gross weight per unit product 36000.000kgProduct Description

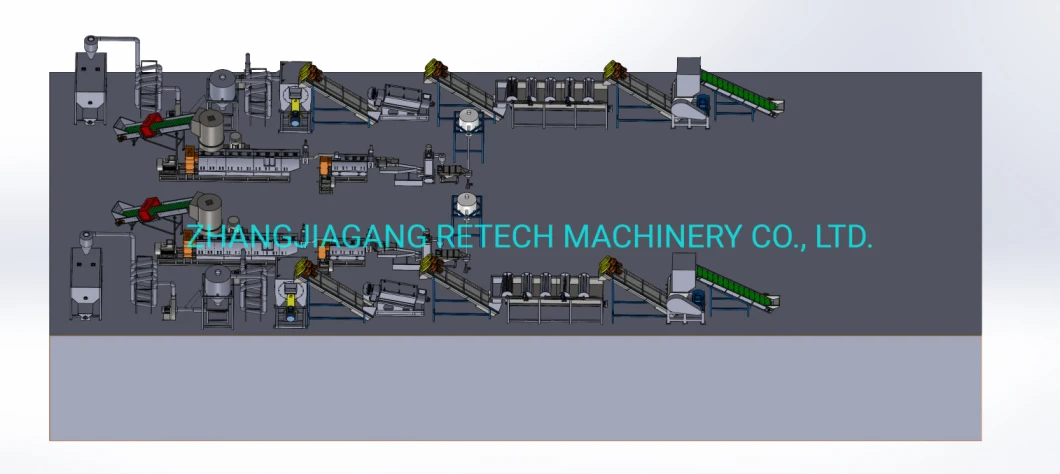

PP PE HDPE LDPE LLDPE Film Agriculture Waste Irrigation Pipe Net Greenhouse Mulch Film Washing Recycling Line

LDPE LLDPE film washing recycling line is working to process waste plastic soft plastic materials. Its is including crushing,washing drying units:

Main Features of LDPE LLDPE Film PP woven bag jumbo bag raffia washing recycling line :1. The main material is PE agriculture film, PE bags, shopping bags, beverage bags, PP woven bags, and some other soft material etc…2. The main process of the washing line is crushing, washing, drying parts. 3. The capacity of the washing line is from 200kg/h to 2000kg/h. 4. There crusher is to crush the film and woven bags to small pieces with size 70mm to 120mm. 5. Cold water sinking swimming tank can wash the common dirties, like the soil, sand, earth, stone, glass out. 6. High speed friction washer and hot sinking swimming tank can remove the strong dirties, like the grease, oil, glue. 7. With big capacity, double drying system can ensure the final products, PE PP flakes moisture lower than 5%.8. With squeezing machine, the moisture level of PE PP flakes can be lower than 3%. 9. Final PP PE flakes can be taken directly to the granulating/pelletizing line to make granules/pellets. * washing line for 99% clean LDPE film (98/2), about 2000kg/hour or two lines of 1000kg/hour*granulation line, about 2000kg/hour or two lines of 1000kg/hour

| Models | Capacity | Total Power | Workers |

| TSWL300 | 300kg/h | 95~150KW | 1~2 |

| TSWL500 | 500kg/h | 180~250KW | 2~3 |

| TSWL1000 | 1000kg/h | 280~380KW | 2~3 |

Prev: Double Shaft Scrap Copper Wire Recycling Electrical Copper Cable Iron Steel Metal Cans Shredder

Our Contact