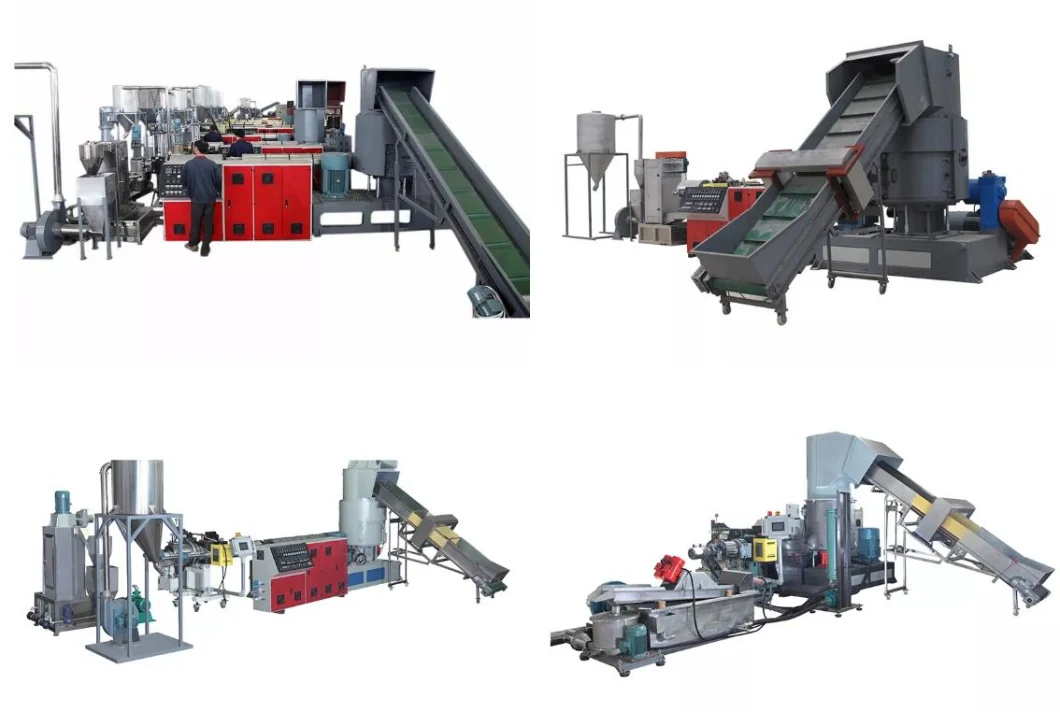

Pet/PP/PE/ Agricultural Film/Woven Bag/Bottle Flakes /Lumps/Board / Pipes Plastic Recycling Washing Pelletizing Machine

HDPE PE PP Film, Woven bag, Jumbo bags, Nylon Fiber Pelletizing Line Product Description: High efficiency automatic pell

Description

Basic Info

| Model NO. | LG |

| After-sales Service | Warranty 12 Months |

| Warranty | Warranty 12 Months |

| Raw Material | PP, PE, PVC, ABS, PS |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| Transport Package | Wooden Box Film |

| Specification | 100-800kg/h |

| Trademark | lianguan |

| Origin | Zhangjiagang, China |

| HS Code | 84778000 |

| Production Capacity | 10 Sets |

Product Description

Product Description:

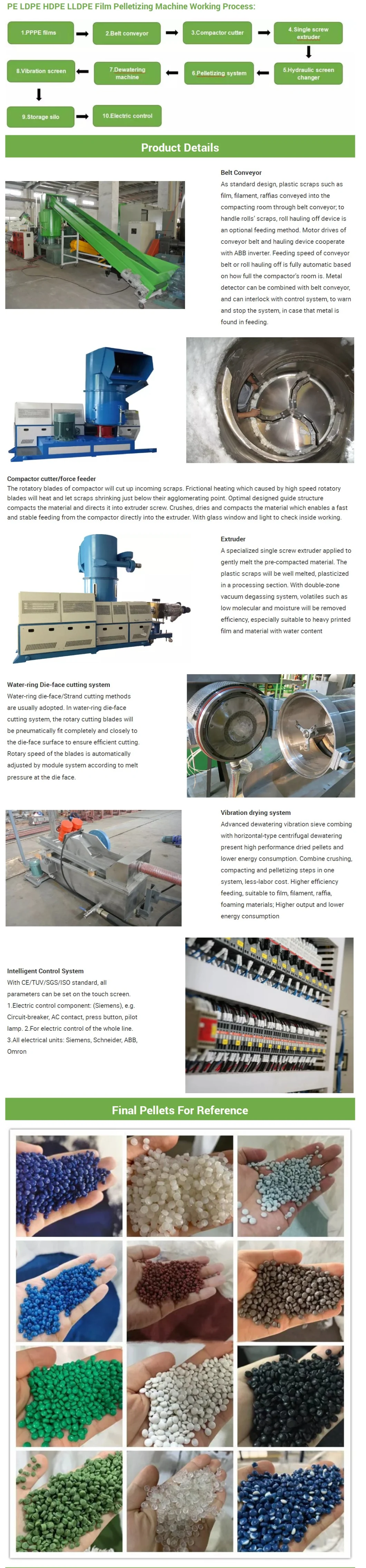

High efficiency automatic pelletizing machine from our company is designed for recycling plastic PP,PE,HDPE,LDPE, LLDPE,PA66,PC,PET,OPP,BOPET,ABS and etc. which are widely used in making bags, film rollers, stretch film, shrink film, multi-layer film, T-shirt bag cut-offs; Foamed PE, sheet, food container, fruit net, cover, fiber, raffia, silk, yarn, woven bag, jumbo bag. One pelletizing machine can produce more than 10 kinds of plastic material.

Recyclable Plastics Include:

* LLDPE/LDPE/HDPE film, crushed material

* PP/OPP/BOPP/CPP film, woven bags, jumbo bags, non-woven fabric (melt blown)

* PA66 fishing net, carpet

* PET/BOPET bottle flakes, film, waste cloth, foam, optical film

* EPS/XPS/EPE/PU/PVC crushed material, cold briquetting foam, hot melt foam, compacted foam, insulation board

* HIPS/PS/ABS home appliance housing, electronic waste, factory plastic

Product Parameters(single stage pelletizing line):

| Model | SJ100 | SJ120 | SJ150 | SJ175 | SJ185 |

| screw diameter(mm) | Φ100 | Φ120 | Φ150 | Φ175 | Φ185 |

| screw L/D | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

| main motor(kw) | 22-37 | 37-75 | 45-110 | 55-132 | 75-160 |

| compactor cutter power(kw) | 37-45 | 45-55 | 75-90 | 75-110 | 90-132 |

| exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

| screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

| pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

| capacity(kg/h) | 100-200 | 200-300 | 300-500 | 500-600 | 700-800 |

Product Parameters(two stage pelletizing line):

| Model | SJ100+SJ100 | SJ120+SJ120 | SJ150+SJ150 | SJ175+SJ175 | SJ185+SJ185 |

| Screw diameter(mm) | φ100+φ100 | φ120+φ120 | φ150+φ150 | φ175+φ175 | Φ185+φ185 |

| mother extruder screw L/D | 20-33 | 20-33 | 20-33 | 20-33 | 20-33 |

| baby extruder screw L/D | 9-12 | 9-12 | 9-12 | 9-12 | 9-12 |

| mother extruder motor power(kw) | 30-37 | 37-75 | 45-110 | 55-132 | 75-160 |

| baby extruder motor power(kw) | 15-22 | 22-37 | 37-45 | 45-55 | 55-75 |

| compactor cutter power(kw) | 37-45 | 45-55 | 75-90 | 75-110 | 90-132 |

| exhaust method | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust | vacuum or natural exhaust |

| screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer | plate or pillar type hydraulic screen changer |

| pelletizing type | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer | water-ring or noodle pelletizer |

| capacity(kg/h) | 100-200 | 200-300 | 300-500 | 500-600 | 700-800 |

SUZHOU LIANGUAN MACHINERY CO.,LTD. is located in the national civilized city-Zhangjiagang, it's near the golden waterway of Yangtze River, only 2 hours from Shanghai Pudong airport by car. It covers an area of 10000 square meters, with two machinery workshop. It's a modernized manufacturing enterprise with machinery, product and technology together. SUZHOU LIANGUAN MACHINERY COMPANY held the mission "turn plastic waste into profit, and make it industrialization", vigorously develop circular economy, We are dedicated to developing and manufacturing the high technology plastic recycling machinery. Our factory has a history of 20 years of equipment processing and experienced engineers which will ensure the quality for you; Our main products machinery are at below: 1- Waste PET Recycling Line used to washing the waste PET bottles into clean PET flakes complete line; 2- Waste Plastic Film, Woven bags/Jumbo bags recycling washing line; 3- Plastic granulator line with different model can used for the waste plastic Film, PP woven bags, Jumbo bags, waste PSF/POY textile and fabric, Nylon and for hard plastics such as PE, PP, PET, PS, ABS, EPS, XPS, etc. 4- Plastic Shredder Machinery include the Single Shaft Shredder Machine, Double/Four Shaft Shredder Machine, Twin Roller Shredder Machine; 5- Plastic Crushers: PET bottle crusher, PPPE film crusher, PIPE crusher. 6- Milling Machine: PVC milling machine, PE milling machine, WOOD milling machine. 7- Plastic Mixer: PVC mixer, PE mixer, Wood Plastic Mixer; 8- EPS Foam material recycling machine which includes EPS hot melting machine, EPS compacting machine, EPS crusher. 9- Auxiliary Machine: Agglomeration Machine, Plastic Film Squeezer, Plastic film squeezing pelletizer machine, etc.

Prev: Dirty Used PE PP Film Rigid Flake Washing Recycling Machine / Waste Plastic Recycle Washing Line

Next: Shredwell Manufacturing Weee Directive Materials Shredding Machine

Our Contact

Send now