Plastic PE/PP/LDPE/LLDPE/BOPP/HDPE/Pet/Bottle/Laminated/Film/Woven Bag/Non Woven/Foil/Crushing Facility/Washing Plant/Dryer Squeezing Machine/Recycling Line

Description

Basic Info

| Model NO. | TPWL300~3000 |

| Plastic Type | PE HDPE LDPE LLDPE PP BOPP Film |

| Screw | Crusher&Shredder |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| Color | Could Be Customized |

| After-Sale Service | Eers Available to Service Machinery Overseas |

| Material of Recycling Machines | Stainless Steel |

| Electric Grid | 3p 220~440V 50 or 60Hz |

| Humidity | 3%-5% |

| Transport Package | Wrap Film |

| Specification | TSWL300~3000 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 300~3000kg/H |

Packaging & Delivery

Package size per unit product 400.00cm * 600.00cm * 500.00cm Gross weight per unit product 26000.000kgProduct Description

Plastic PE/PP/LDPE/LLDPE/BOPP/HDPE/Pet/Bottle/Laminated/Film/Woven Bag/Non Woven/Foil/Crushing Facility/Washing Plant/Dryer Squeezing Machine/Recycling Line

Our Plastic PP PE LDPE LLDPE HDPE film bag crushing washing recycling line is working to process different kinds of plastics like PE film,PP woven bags,etc.By crushing,constantly washing,high efficiency drying performance,film will be very cleand and dry.

Features

Main Features of RETECH PP PE film washing recycling line:

1. The main material is PE agriculture film, PE bags, shopping bags, beverage bags, PP woven bags, and some other soft material etc…2. The main process of the PP PE film washing line is crushing, washing, drying units. 3. The capacity of the LDPE film washing line is from 300kg/h to 2000kg/h. 4. The crusher is to crush the film and woven bags to small pieces with size 70mm to 120mm. 5. Cold water sinking swimming floating tank can wash the common dirties, like the soil, sand, earth, stone, glass out. 6. High speed friction washer and hot sinking swimming tank can remove the strong dirties, like the grease, oil, glue. 7. With big capacity, double drying system can ensure the final products, PE PP flakes moisture lower than 5%.8. With film squeezing machine, the moisture level of PE PP flakes can be lower than 3%. 9. Final PP PE flakes can be taken directly to the granulating/pelletizing line to make granules/pellets.

| Models | Capacity | Total Power | Workers |

| TSWL300 | 300kg/h | 95~150KW | 1~2 |

| TSWL500 | 500kg/h | 180~250KW | 2~3 |

| TSWL1000 | 1000kg/h | 280~380KW | 2~3 |

1. What is the function of the PE PP film washing recycling line?

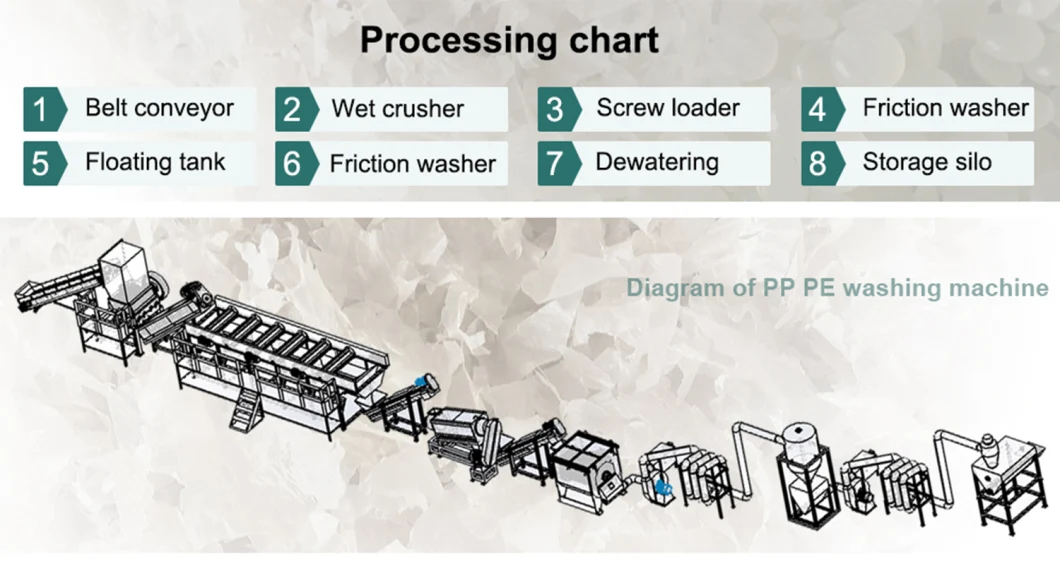

The PE PP film washing recycling machinery is used to recycle and process the PE agriculture film, PE bags, shopping bags, beverage bags, PP woven bags, and some other soft material etc…2. Where does it collect the waste material for the PE PP film washing recycling machines? The waste mater is gotten mainly from agriculture film, city rubbish and plant in bale package or separated. They are with much dirties, such as the earth, soil, sand, stone, glue, grass, oil, and some other dirties. But by our many years experience to manufacture the washing line, we can promise to wash the material clean enough to take the washed material into the extruder to make granules. We have our special design to guarantee this point. 3. What are main parts of the PE PP film washing recycling machines?The following is a standard structure of the PE PP film washing recycling machinery:Belt conveyer--- crusher with water--- screw conveyer--- floating washer--- screw conveyer--- high speed friction washer--- high speed friction washer--- screw conveyer--- horizontal centrifugal dewatering machine (or squeezer)--- drying system 1--- transition hopper--- drying system 2--- storage silo--- operating panel The up is a standard structure of the line, we can adjust it to remove some parts or add some parts due to the situation of the material or customers' requirements.4. What capacity of the PE PP film washing recycling machinery?300-2000kg/h for single washing line5. What power of the PE PP film washing recycling machines?150kw~480kw6. How much water does it need of the PE PP film washing recycling machines?4~10T per hour 7. How large space does it need for a PE PP film washing recycling machines?100~400 square meters, the whole line could be installed by straight, "L" shape or "U" shape. We could design how to instal the machines due to the space of your factory. 8. What is the condition of the final products from the PE PP film washing recycling machines? The size of final flakes will be 50~100mm, and final moisture level of film flakes will be lower than 5%. The PP PE flakes can be taken directly to the granulating/pelletizing line to make granules/pellets.9. What is material of the PE PP film washing recycling machines?The parts contacted with water are made of stainless steel SUS 304 or customized. 10. What certifications do you have for the PE PP film washing recycling machines?We have CE and ISO9001 certification for the entire PE PP film washing recycling machines.plasticmachine.en.made-in-china.com

Prev: Wedo Machinery Professional Sales Team Made in China Zig Zag Sorting Machine, Zig Zag Separator

Our Contact