Immersed Mbr Membrane for Waste Water Treatment/Industry ETP/Domestic Sewage/Landfill Leachate Treatment/PVDF Mbr Membrane/Cross Refer: Kubota and Toray

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biolog

Description

Basic Info

| Model NO. | FMBR80-125 |

| Type | Microfiltration Machine |

| Method | Physical Treatment |

| Usage | Industrial |

| Membrane Material | PVDF |

| Membrane Pore Size | 0.1um |

| Plate Size | 1810*512*14mm |

| Plate Material | ABS |

| One Module Membrane Area | 40 - 200 Square Meters |

| Air Flow Rate | 10-12L/Min for Each Plate |

| Frame Material | SS304 |

| Permeate Flux | 16-130 M3/Day |

| Transport Package | Wooden Box |

| Trademark | RisingSun |

| Origin | China |

| HS Code | 84212990 |

| Production Capacity | 1000piece / Month |

Product Description

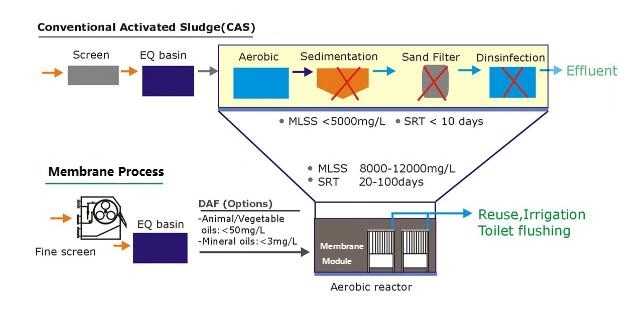

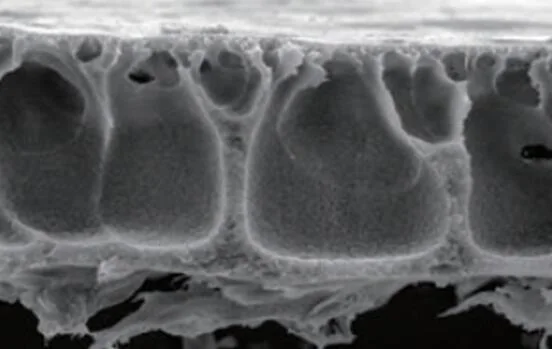

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process and the activated sludge process.MBR process VS traditional wastewater treatment process.You can see MBR module systems replace the Clarifier, Sand filter and Disinfection processes used in Conventional Activated Sludge (CAS) process by removing the suspended materials with UF/MF membrane. The membrane modules are submerged in a biological tank or side streams tank, with the water being drawn through the membranes under vacuum, leaving the suspended biomass material in the biological aeration tank. The MBR systems have a smaller footprint than CAS systems, produce consistent effluent quality even in varying influent conditionsIt is now widely used for municipal and industrial wastewater treatment.RisingSun flat sheet membrane is made of PVDF material, which has better chemical stability, fouling resistance and mechanical strength. With advanced membrane fabrication technology, we control the membrane pore size around 0.1 um to get a higher water flux and water quality.Benefits:The mortise and tenon structure is used in the support plate to get a more stable spacing without side panels. The support plate can be installed from top or one side without the limits of the construction site conditions. SUN® support plate

MBR membrane module specifications:

| Items | FMBR80 | FMBR160 | |||||||

| Model | FMBR80-50 | FMBR80-125 | FMBR160-50 | FMBR160-125 | |||||

| Permeate flux (m3/d) | 16-26 | 38-65 | 32-50 | 75-130 | |||||

| Plate qty. (pc) | 50 | 125 | 50 | 125 | |||||

| Membrane effective area (m2) | 40 | 100 | 80 | 200 | |||||

| Size (mm) (L×W×H) | 820X600X1680 | 1885X600X1680 | 830X620X2550 | 1880X620X2550 | |||||

| Air flow rate (L/min) | 500 | 1250 | 600 | 1500 | |||||

| Weight (kg) | 120 | 230 | 400 | 900 | |||||

MBR completed module pictures:

Immersed MBR Cassette for Waste Water Treatment/Industry ETP/Domestic sewage/Landfill leachate treatment/

PVDF membrane Cross refer: Kubota and Toray Japan

FAQ

1, Q: Are you manufacturer? A:Yes, definitely,our factory locate in Beijing,China. 2, Q:What's your main products ? A: we manufactur filter membranes, RO, NF, UF, MF membrane, spiral wound/flat sheet membrane, tubular membrane, MBR, DTRO,STRO,E-coat UF membrane, anode cell etc. 3, Q: what's your main market? A:There're about 94 countries we've been exported, mainly in USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc. 4, Q:Can you supply free sample? A:Yes, we can supply free samples which are in stock, and the freight charge should be on your side. 5, Q: What about the package? A:The membrane elements are wrapped with plastic bubble paper, then carton box, safe wooden box outise, the breakage is less than 1%. 6, Q: Do you offer OEM? A: Sure!

Prev: Powdered Activated Carbon for Waste Water Treatment

Next: SS316 314 Falling Film Vacuum Evaporator for Waste Water Treatment

Our Contact

Send now