Plastic/LDPE/PE/PP/HDPE/LLDPE/BOPP/Film/Foil/Woven/Bags/Raffia/Centrifugal/Dewatering/Squeezing/Squeezer/Pelletizing/Pelletizer/Dryer/Machine

Description

Basic Info

| Model NO. | TSD300~1000 TSP300~1000 |

| After-sales Service | Video Technical Support, Free Spare Parts, Field I |

| Warranty | 1 Year |

| Material Processed | Film |

| Plastic Type | HDPE LDPE LLDPE PP Film |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| Color | Could Be Customized |

| Type of Extruder | Connical Screw |

| After-Sale Service | Engineers Available to Service Machinery Overseas |

| Stage | Single Stage Semi-Plasticized or Plasticized |

| Feeder Type | by Conveyor |

| Capacity | 200~1200kg/H |

| Transport Package | Wrap Film |

| Specification | TSD300~1000 TSP300~1000 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 300~1500kg/H |

Packaging & Delivery

Package size per unit product 400.00cm * 220.00cm * 200.00cm Gross weight per unit product 2300.000kgProduct Description

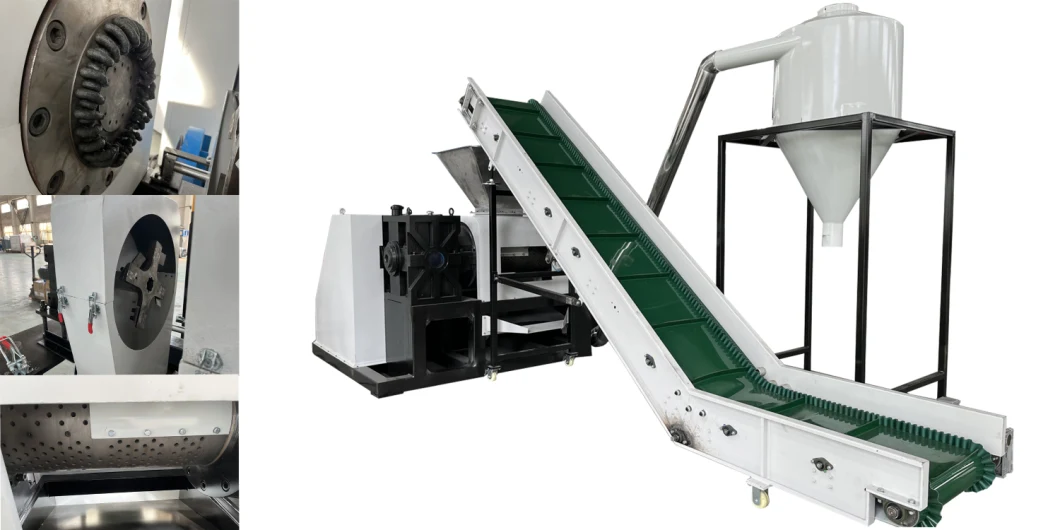

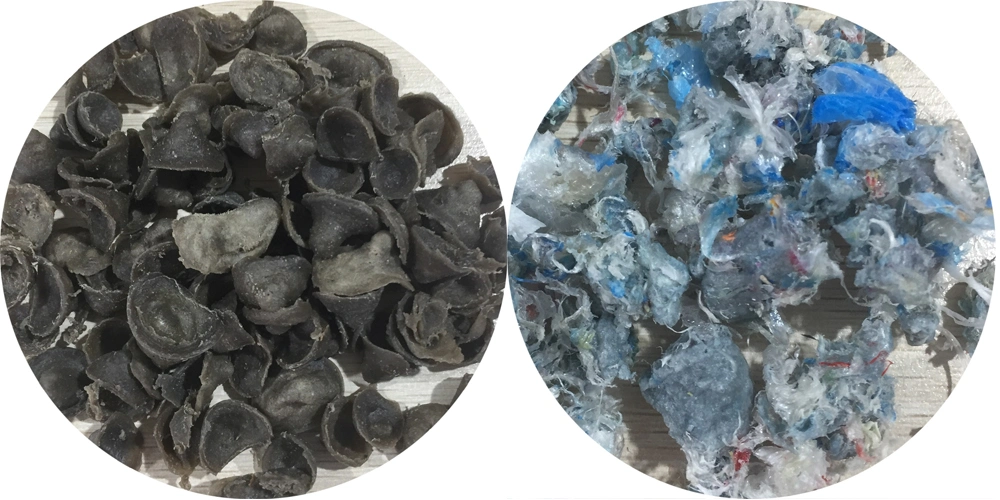

Plastic/LDPE/PE/PP/HDPE/LLDPE/BOPP/Film/Foil/Woven/Bags/Raffia/Centrifugal/Dewatering/Squeezing/Squeezer/Pelletizing/Pelletizer/Presser/Compressor/Dryer/Machine Product DescriptionOur Plastic PP PE Film Squeezing Machine is used for drying those washed LDPE LLDPE film, PP woven bags.etc. And make it like granules.It is a full automatic Squeezing & Compacting & Pelletizing Machine to the film and woven bags, with the screw squeezing and electrical heating, make the materials have high degree of drying and full plasticizing, low power consumption, high output. The final moisture is only 3-5%. The capacity would be customized according to the requests of clients.Our plastic film squeezer is used for squeeze and re-pelletizing PP/PE film, woven bag, ton bags, nylon etc. it's equipped with advanced screw extrusion system, squeezing efficiency could reach 95%. Also can work on the accordance with washing and pelletizing line with stable capacity and whole process automation.Plastic film squeezer usually in position of ending part of below recycling machine:1. LDPE waste film recycling and washing line2. PE agriculture using films crushing and washing line3. Waste PE film recycling line4. Ethylene ground film washing, drying and regranulating line5. Waste film recycling and washing line6. PP woven bag recycling and washing line

| Technical parameters: (1) Motor power:90kw,110kw,132kw,160kw,185kw (2) Speed of screw: 0-90r/m (3) Type of gearbox: 315 type,330type,375type(4) Material of Screw: 38CrMoA1A, nitride treatment, hardness: HV740, depth of nitride layer: 0.4~0.6mm(5) Material of Barrel:38CrMoA1A, nitride treatment, hardness: HV≥980, depth of nitride layer: 0.6~0.7mm(6) Screw diameter:300mm,320mm,380mm(7) L/D: 6:1(8) Cutting blades power:3kw(9) Blowing power:5.5kw(10) Way of water drain: at the bottom of machine(11) Volume of hopper:0.5 cube meter(12)Electrics:Contactor, Pioneer Inverter, Automatic Control (13)Capacity:300-800kg/h(PE PP film) |

| 1 | Motor Power | 75kw | 90kw | 132kw | 160kw |

| 2 | Screw Diameter | 250mm | 300mm | 320mm | 380mm |

| 3 | Cutting Power | 2.2kw | 3kw | 5.5kw | 7.5kw |

| 4 | Screw Material | 38CrMoA1A,Nitrogen treatment | |||

| 5 | Heating Power | 9kw | 12kw | 15kw | 18kw |

| 6 | Moisture | Less than 3% | |||

| 7 | Capacity | 300kg/h | 400kg/h | 600kg/h | 800kg/h |

Advantages of RETECH PP PE film squeezing dryer machine:

1. Unique screw squeezing design removing moisture theory, solving the common problem that it is hard to dry the wet film during the plastic film drying recycling field. 2. Good drying performance, could make the final moisture level lower than 3%. 3. Advantage technology, lower power consumption, lower noisy, easy operating and maintenance, safe running and high cost performance. 4. Mechanical squeezing dewatering way, comparing with the traditional centrifugal and hot air drying dewatering way, could save space and energy much more.

Contacts:

RETECH Machinery is an experienced and professional manufacturing for series plastic washing recycling machine/ plastic granulating recycling machine including PET bottle recycling machines, PE PP film recycling machines, plastic PE PP PS ABS PET PC PVC LD HD LLD BOPP granulating line, water treatment for the waste water from washing line, and auxiliary equipment for plastic recycling....If you are interesting more details of our products, please contact with us no hesitation!plasticmachine.en.made-in-china.com

Our Contact