New Design HDPE LDPE LLDPE BOPP PP PE Film Woven Bag Jumbo Bag Pet Bottle Waste Plastic Crushing Washing Recycling Waste Recycle Line

Description

Basic Info

| Plastic Type | PE |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Computerized |

| Certification | CE |

| First Name | Plastic Film Recycling Granulating Machine |

| Screw Barrel | Bimetalic |

| Gearbox | Shuguang |

| Screen Changer | Hydraulic Automatic |

| Motor | Siemens |

| Inverter | ABB |

| Main Electrical Part | Siemens and Schneider |

| Warantee Time | 12 Months |

| After Sales Service | Engineer Overseas Service |

| Machine Condition | New Machine |

| Capacity | 300kg/H-1500kg/H |

| Condition | New |

| Key Selling Points | Multifunctional |

| Place of Origin | China |

| Machine Type | PP PE Film Washing Line |

| Transport Package | Wooden Base |

| Specification | CE, SGS |

| Trademark | Sino-Tech |

| Origin | Jiangsu, China |

| HS Code | 8477800000 |

| Production Capacity | 200sets/Year |

Packaging & Delivery

Package size per unit product 26000.00cm * 18000.00cm * 15000.00cm Gross weight per unit product 80000.000kgProduct Description

PE PP Washing Line Waste Plastic Recycling Machine

PP PE plastic washing recycling machine is widely used to washing recycling the used PP/PE plastic soft plastic. Such like shopping bags, packing films, garbage bags, woven bags, non-woven bags and films. This recycling machine can crushing washing and drying the dirty soft plastic into clean film flakes.After plastic film/bag flakes cleaned, you can make them into pellets/granules with next process, which called plastic pelletizing machine.This production line is high automatic operating and low consume, can save labor, save power and save water, easy to maintenance.With advanced design, concepts and technologies to suit different status of waste plastic bags/films. This PP PE plastic recycling machine could layout as "L", "S" or "U" shape according different workshop.

Product Description

| 500kg/hour PE PP Film Washing Recycling Line is include below: | ||||

| No | Machine name | Qty(set) | ||

| 1 | Belt conveyor | 1 set | ||

| 2 | Crusher with water GS1000 | 1 set | ||

| 3 | Friction washing machine | 1 set | ||

| 4 | Floating washing machine | 1 set | ||

| 5 | Screw feeder | 1 set | ||

| 6 | Dewatering machine | 1 set | ||

| 7 | Pipe drying system | 1 set | ||

| 8 | Storage hopper | 1 set | ||

| Capacity | Power Consumption | Water Consumption depend material | Labour | Humidity Content |

| 300KG/H | 130KW | 3-4 ton/h | 1-2 | <5% |

| 500KG/H | 150KW | 4-5 ton/h | 1-2 | <5% |

| 1000KG/H | 180KW | 6-8 ton/h | 3-4 | <5% |

| 1500KG/H | 240KW | 8-10 ton/h | 4-5 | <5% |

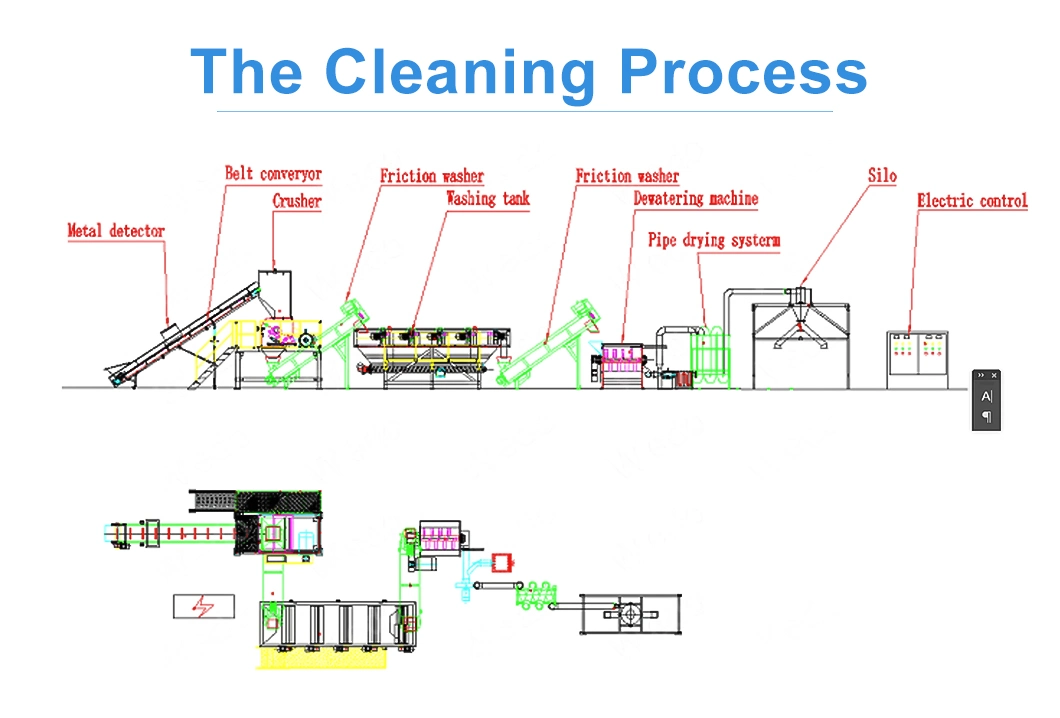

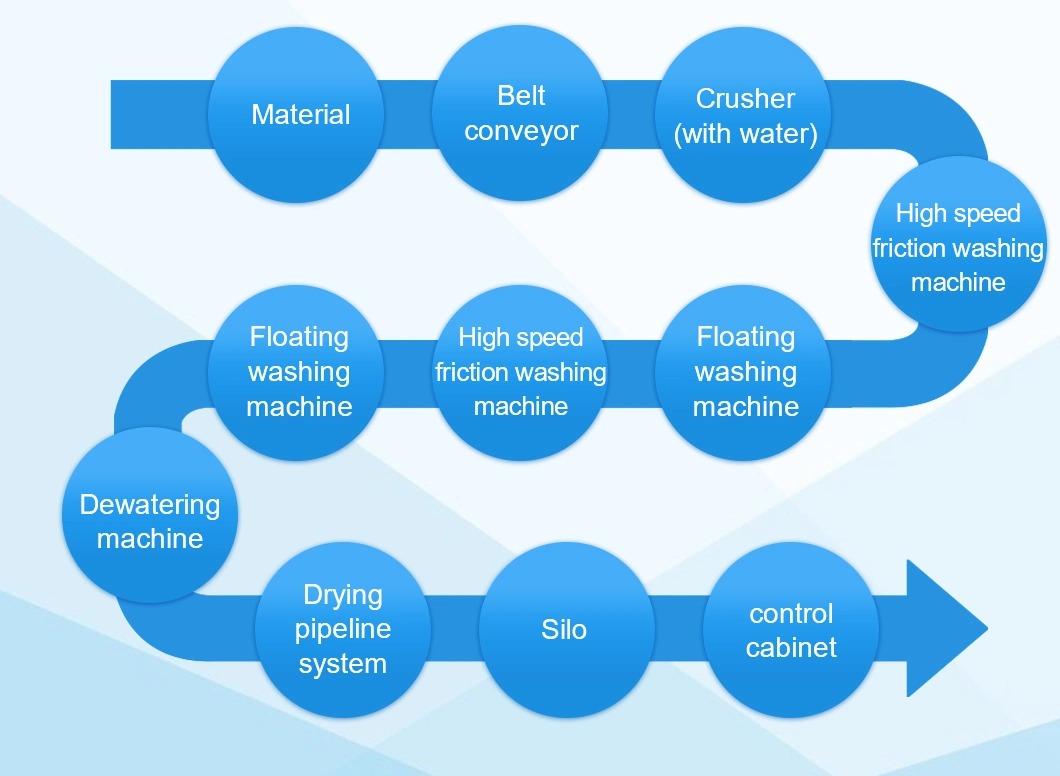

The whole line includes

Belt Conveyor: The materials go into the crusher by the crawler belt, which is moved by inside scroll wheel.Crusher: Crush the material.Screw Loader: Put the flakes into the Hot washer to clean.Hot Washer: If the bottle is very dirty, like oil, sand, it must be use hot washer.Screw Loader: Put the flakes into the High-speed Friction Washer to clean.High-speed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect.Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.Floating Washer 2: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.Dewatering: Rejection the water from the flakes, moisture content is less than 2%.Drying Pipe lineSilo: Storage materials.Electrical Control Cabinet

Belt conveyor → Crusher (with water) → High speed friction washing machine → Floating washing machine(Can be hot washer) → High speed friction washing machine → Floating washing machine → dewatering machine → drying pipeline system → Silo→control cabinet

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

Prev: Shredder for Recycling Car Tyre

Next: Hard Plastic Recycling Machine Plastic Bottle Sinlge Shaft Shredder Machinery for Pet

Our Contact