MT Series Plastic PET PE PP Crusher Granulator Washing and Recycling Recycling Line

Description

Basic Info

| Model NO. | MT Series |

| After-sales Service | Engineers available to service machinery overseas |

| Warranty | 1 Year |

| Material Processed | Plastic Bottle |

| Plastic Type | PET |

| Screw | According to Model |

| Automation | Automation |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Name | Plastic Recycling Machine |

| Automatic Grade | Automatic |

| Capacity | 300-3000kg/H |

| Final Products Size | 8-16mm |

| Plant Area | > 400-1000 Square Meter |

| Machine Material | Stainless or Carbon Steel |

| Machine Color | Suitable for Your Factory |

| Manpower | 8-10 Persons Required |

| Water Consumption | About 2-3 T/Hr |

| Usage | Plastic Recycling |

| Transport Package | Standard Package Plastic Recycling Machine |

| Specification | MT300-3000 plastic recycling machine |

| Trademark | Mooge plastic recycling machine |

| Origin | China Plastic Recycling Machine |

| HS Code | 84778000 |

| Production Capacity | 50 Lines/Year Plastic Recycling Machine |

Product Description

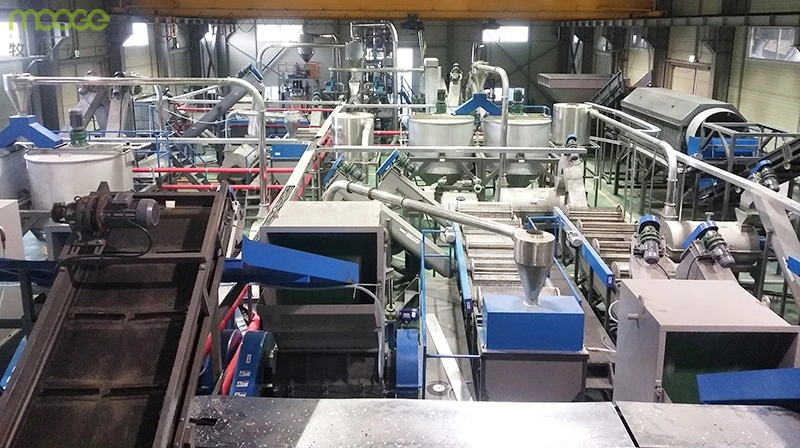

MT Series Plastic PET Recycling Line

Product Description

China Factory Water Bottle Washing Machine Cleaning is mainly used to recycling the waste PET bottles, water bottles, cola bottles, PET sheet and PET packing containers. The Recycled waste cola bottle PET recycling machine can easily remove the labels, caps, rings, glue, dirties and other impurities, finally you will get ideal PET flakes.All your requirements of the Recycled waste cola bottle PET recycling machine will be customized.

Product Parameters

We have 500-5000 kg/h MT Series Efficient plastic recycling machine.and We can design the layout according to your requirements.

| Model | Capacity | Installed Power | Steam Use | Water Supply | Manpower | Area Required (L*W*H) |

| MT-500 | 500kg/hr | 190 KW | Optional | 4-5 m3/hr | 4-6 Person | 60*5*5 m |

| MT-1000 | 1000kg/hr | 260 KW | Optional | 6-8 m3/hr | 8-10 Person | 80*8*5 m |

| MT-2000 | 2000kg/hr | 400 KW | Optional | 10-15 m3/hr | 10-12 Person | 80*8*5 m |

| MT-3000 | 3000kg/hr | 600 KW | 80,000 Kcal | 20-30 m3/hr | 12-16 Person | 100*8*10 m |

| MT-4000 | 4000kg/hr | 800 KW | 100,000 Kcal | 30-40 m3/hr | 15-20 Person | 135*10*10 m |

| MT-5000 | 5000kg/hr | 1000 KW | 120,000 Kcal | 40-50 m3/hr | 15-20 Person | 135*10*10 m |

Features At A Glance

De-Baling MachineFunction: Opening the PET bottle bales

With 4 roller cylinder to feeding the bottles equally. Claw steel is very strong and the thickness is 20mm.

Machine chamber made by solid strong steel. Working chamber size can above 1600x1600mm(depth x width).

Machine fixed with support over the sorting table

Trommel Machine

Function: loose pet bottle and remover caps, sand, soil and feeding the bottles out constantly.

The track and gear made by one unit steel with forging steel strong and heating treatment.With high platform with dirty collecting chute, put the jumbo bags under the Trommel.

Label Remover Machine

Function:remove the labels from the bottle and separate label out from bottles.

Blade made by alloyed steel for long time use.Blade is fixed by screw on the rotor easy to adjustable and changeable.The barrel is designed with doors opening on it very easy to opening and maintenance .The machine bottom with holes to drain out liquid which contained in the bottles, good for machine use.

Plastic Crusher Machine

Function: crushing the bottles to PET flakes.

With water inlet do wet crushing. Chamber opened by screw motor.Specially designed PET bottle Crusher Machine can easily get high output and with water doing wet grinding can extension the blades use life, reduce the dust generation.Bearing house is outside of the crusher chamber so no dirty goes inside for longer use.

Hot Washing Tank

Function: with hot water washing to remove oil/glue and other dirty from the flakes.The tank made with insulation layer to save energy.Feeding caustic soda/detergent to washing Its better Heating by steam,You can buy a steam boiler to produce the steam.The boiler can heating up by gas/diesel/petrol/LPG

Floating Washing Tank

Function: Used to wash the flakes, with the top rollers automatic take out the caps/rings and other impurities, flakes sinking down and take out by screw.

With the rollers working will use less water to take out the caps/rings.

With double screw.

Rotor shaft made by seamless steel tube.With drain hole on the bottom of tank.

Installation Instructions

MT-1000 PET bottle recycling washing machine in Korea

MT-2000 PET bottle recycling washing machine in South Africa

MT-5000 PET bottle recycling washing machine in Algeria

Packaging & Shipping

Company Profile

Our Contact