Industrial Waste Water Treatment Automatic Sludge Dewatering /Thickening Filter Press Suppliers for Coking Wastewater

Package size per unit product 479.00cm * 292.00cm * 245.00cm Gross weight per unit product 5100.000kg Yixing Pioniere En

Description

Basic Info

| Model NO. | XF-T404 |

| Method | Physical Treatment |

| Usage | Industrial, Agriculture |

| Press Type | Screw Type |

| Certification | CE/ISO |

| Material | SUS304 |

| N.W. | 5000kg |

| Process Capacity | 48-360cbm/H |

| Ds Output | 720-1200kg/H |

| Power | 8.2kw |

| Transport Package | Wooden Case/Container |

| Specification | 4590*2720*2250mm |

| Trademark | Pioniere |

| Origin | Jiangsu, China |

| HS Code | 8421191000 |

| Production Capacity | 300pieces/Year |

Packaging & Delivery

Package size per unit product 479.00cm * 292.00cm * 245.00cm Gross weight per unit product 5100.000kgProduct Description

Yixing Pioniere Environmental Protection Equipment.Product Description:

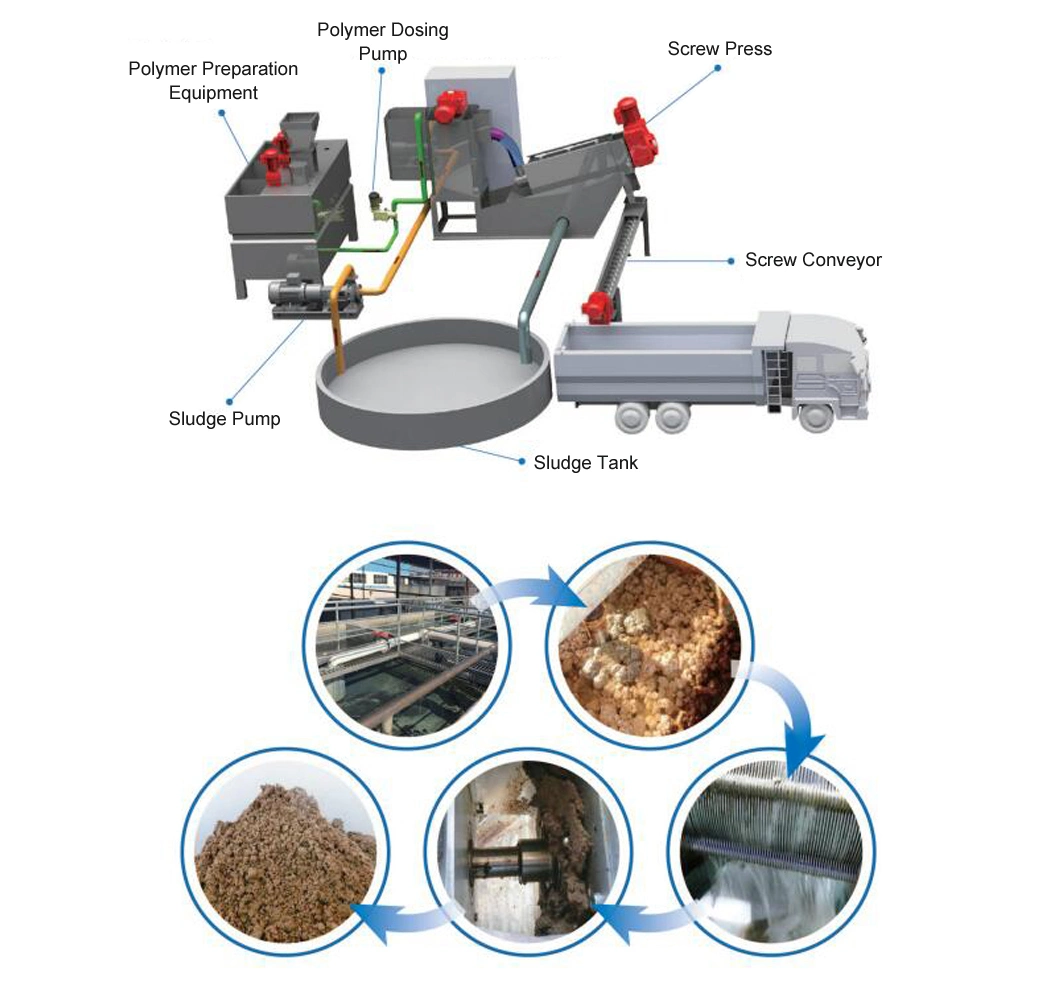

Screw Type Sludge Thickening Equipment is usually used for sludge after biological process and thickening prior to storage, digestion and further dewatering. In WWTP, sludge concentration is about 0.2%-2%. After thickening, the solid content reaches 5% to 9%. Thus stable thickened sludge is provided for further dewatering equipment such as frame press and other machines. Also the dewatering efficiency and capacity are improved. Product Details:

Working Principle:

As equipment starts running, sludge flows into the filter cylinder and moves forward to sludge cake outlet under the thrust from screwshaft. The whole filter cylinder is composed of fixed rings, moving rings ans shaft. The first two sections are thickening zone, last two are dewatering zone, The space between screw blades gets more and more narrower, which means the inner pressure gradually gets bigger.. Under this pressure, liquid is squeezed out from the sludge and leaks from the small gaps between rings. And the left dry solid is pushed to the sludge cake outlet.

Specification:

| Model No. | DS standard Capacity(Kg/h) | Sludgevolume(m³/h) | Dimension(mm) | Power(KW) | N.W.(KG) | |||

| Lowconcentration | Highconcentration | L | W | H | ||||

| XF-T401 | 180 | 300 | 12~90 | 4400 | 1010 | 2250 | 2.25 | 2100 |

| XF-T402 | 360 | 600 | 24~180 | 4500 | 1580 | 2250 | 4.1 | 3150 |

| XF-T403 | 540 | 900 | 36~270 | 4590 | 2150 | 2250 | 6.0 | 4100 |

| XF-T404 | 720 | 1200 | 48~360 | 4590 | 2720 | 2250 | 8.2 | 5000 |

Features:

♦ Energy, water, polymer saving

♦ Compact design, small floor space

♦ Low-speed operation, low power consumption and noise

♦ Self-cleaning, free of clogging, easy to handle oily sludge

♦ 24h automatic continuous control, simple operation and maintenance

♦ Widely applied in municipal sewage, papermakingm, chemical industry, food and beverage processing, pharmacy, petroleum refining and extraction, breeding and slaughtering and other industrial wastewater.

Process Diagram:

Cases:

Remarks:

♦ Moisture content output is in the range of 91% - 95%.

♦ Sludge type, sludge volume, solid content and daily runtime of machine are necessary for better model selection.

♦ Raw material is SS304 or SS316 (according to different sludge types,sludge containing much chloride ion needs SS316).

♦ Custom-made is available.

Certification:

Workshop:

Our Contact

Send now