Eddy Current Separator for Professional Copper & Aluminum Sorting

Description

Basic Info

| Model NO. | WL50P |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Blue |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Years for Free |

| Dimension(L*W*H) | 3670X2000X1285mm |

| Motor | Nord |

| Belt | Forbo Siegling |

| Bearing | NSK |

| Reducer | Schneider |

| Processing Capacity | as Required |

| Transport Package | Export Packing |

| Specification | ISO |

| Trademark | JSYY |

| Origin | Fushun, Liaoning, China |

| HS Code | 85051190 |

| Production Capacity | 50sets/Month |

Product Description

Why choose us

Fushun Ejet Magnetic Equipment Co, Ltd 1. It has been focusing on designing and manufacturing magnetic equipment for 12 years2. Participated in exhibitions at home and abroad many times since 2006.3. We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia.4.Our could also supply you the complete resource recycling solutions such as ASR recycling, Zorba and Glass Cullet recycling5.We can tailor our design to meet your request.Product details

| Product name | Eddy current separator |

| Application | Nonferrous metal separation |

| Principle | Magnetic separation |

| Usage | Aluminum Copper sorting |

| Feeding size | ≥3mm |

| Processing capacity | 0-12ton/hour |

| Recovery rate | 98.5 - 99.5 % |

| Installation | Engineer Guidance |

| Voltage | customized according to the customers requirement. |

| Color | As required |

| Product Keywords | nonferrous separators |

High quality plastic sorting recycling machine eddy current separator plastic PVC flakes sorting machine

| Model | ECS65P | ECS80P | ECS100P | ECS120P | ECS150P | ECS180P |

| Magnetic roller diameter (mm) | 500 | 500 | 500 | 500 | 500 | 500 |

| Magnetic roller speed (r/min) | 0-3100 | 0-3100 | 0-3000 | 0-3000 | 0-3000 | 0-3000 |

| Belt Width (mm) | 650 | 800 | 1000 | 1200 | 1500 | 1700 |

| Belt Speed (m/s) | 0-2 | 0-2 | 0-2 | 0-2 | 0-2 | 0-2 |

| Power (kw) | 4.0+1.1 | 4.0+1.5 | 5.5+1.5 | 5.5+2.2 | 5.5+2.2 | 5.5+3.0 |

| Weight(kg) | 2000 | 2500 | 2900 | 3600 | 3800 | 3900 |

| CBM(mm) | 3670*1650*1285 | 3670*2000*1285 | 3670*2300*1285 | 4160*2400*1285 | 4160*2600*1285 | 4160*2800*1285 |

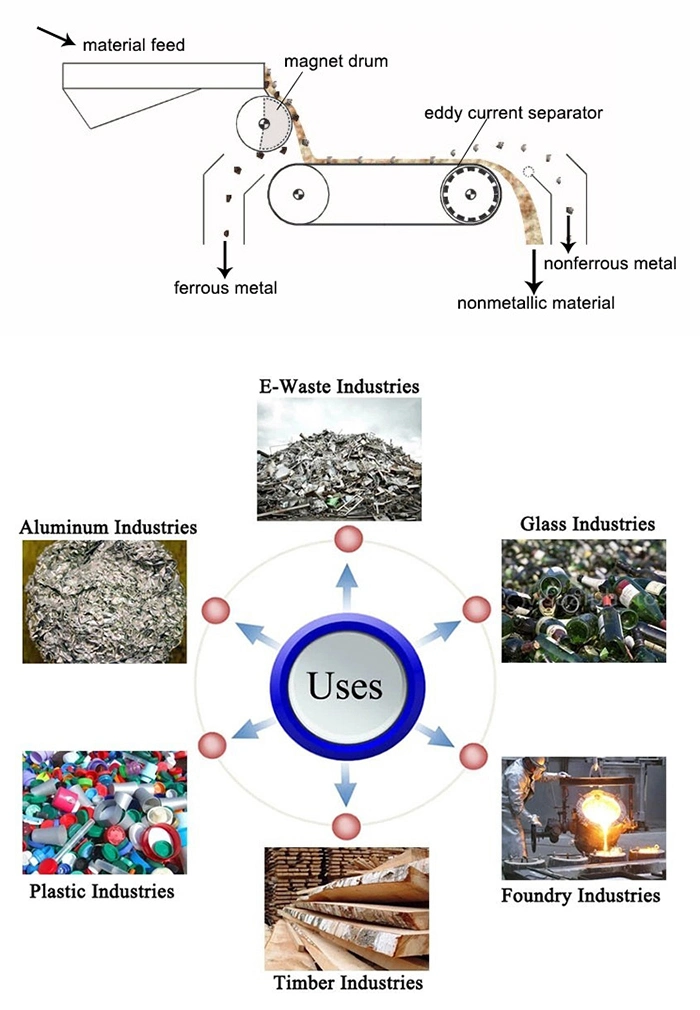

Working principle

To avoid the eddy current belt and eddy current magnetic rotor damage caused by impurity ferrous metal. The Ideal format for any metal separation is first magnetic ferrous separation Copy the url to the browser to see the Magnet drum OR Contact us

https://fsyjjq.en.made-in-china.com/product/keywordSearch?word=overband&subaction=hunt&style=b&mode=and&code=0&comProvince=nolimit&order=0&isOpenCorrection=1

Applications:

Such as

1.Separate the non-ferrous metals from smash material

2.Separate aluminum and copper from aluminum bronze casting sand and smelting ash

3.Remove aluminum cap from a glass bottle

4.Separate aluminum and copper from lump material

5.Separate the non-ferrous metals from incineration of printing plate

6.Separate aluminum cans from the city rubbish

7.Separate aluminum wire and aluminum alloy

1. Q:What kind of metal is eddy current separator applied to?

A:Eddy Current Separator suitable for aluminum, copper, brass.etc non-ferrous scraps separation from non - metal materials of size >3mm.

2. Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition , size ,handling capacity and expected separation result .

3. Q. What is the MOQ of your machine?

A: Our MOQ is 1 set

4. Q:What are the pros and cons between a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much suitable for complicated material situation , The eccentric rotor design reduces long-term wear due to heated ferrous build up ,can effectively avoid the device damage caused by impurity ferrous metal.Exclusive the ferrous influence , the concentric type have a little bit better separation effect,but must make sure no ferrous exist.

5. Q. How long is the machine warranty period?

A: the product warranty period is 12 months

For details, or for longer the machine Warranty Period.

Prev: Hard Plastics Washing Line Waste PE Recycling Machine

Next: High Capacity E-Waste Scrap Recycling Shredder Machine with Best Price

Our Contact