300-1000kg/H Used Pet Water Bottle Recycling Crushing Washing Line

Package size per unit product 100.00cm * 50.00cm * 50.00cm Gross weight per unit product 10.000kg PET washing line/PET b

Description

Basic Info

| Model NO. | 300kg/h, 500kg/h, 1000kg/h, 1500kg/h, 2000kg/h |

| Plastic Type | PET |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Computerized |

| Certification | QS, GMP, ISO9001:2008, CE |

| Certificate | CE ISO SGS Cnas |

| Authentication | ISO9001:2008 |

| Motor | Siemens |

| Control | PLC Touch Screen |

| Suitable Plastic | Pet Bottle, Water Bottle |

| Label Remover | Yes, 100% |

| Cap Remover | Yes, 100% |

| Moisture | <1% |

| Transport Package | Seaworthy Packing |

| Specification | CE ISO9001: 2008 SGS |

| Trademark | horse Rider |

| Origin | Jiangsu |

| HS Code | 84778000 |

| Production Capacity | 100-2000kg/H |

Packaging & Delivery

Package size per unit product 100.00cm * 50.00cm * 50.00cm Gross weight per unit product 10.000kgProduct Description

PET washing line/PET bottle washing linePET flake washing line (including crushing, washing, drying, granulating)

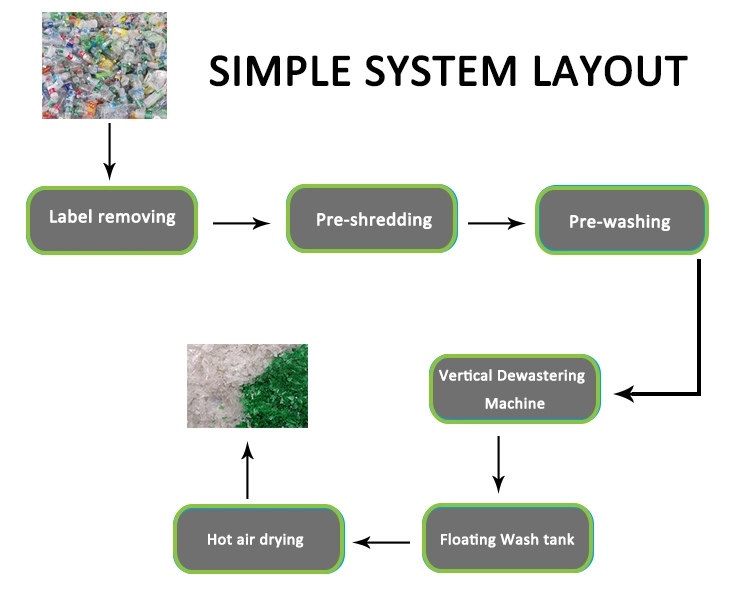

This recycling line is composed of garbage separation (automatic & manual), bottle & flake crushing, cold & hot washing & cleaning, flake dewatering & drying, dust & label removal, packing, etc.

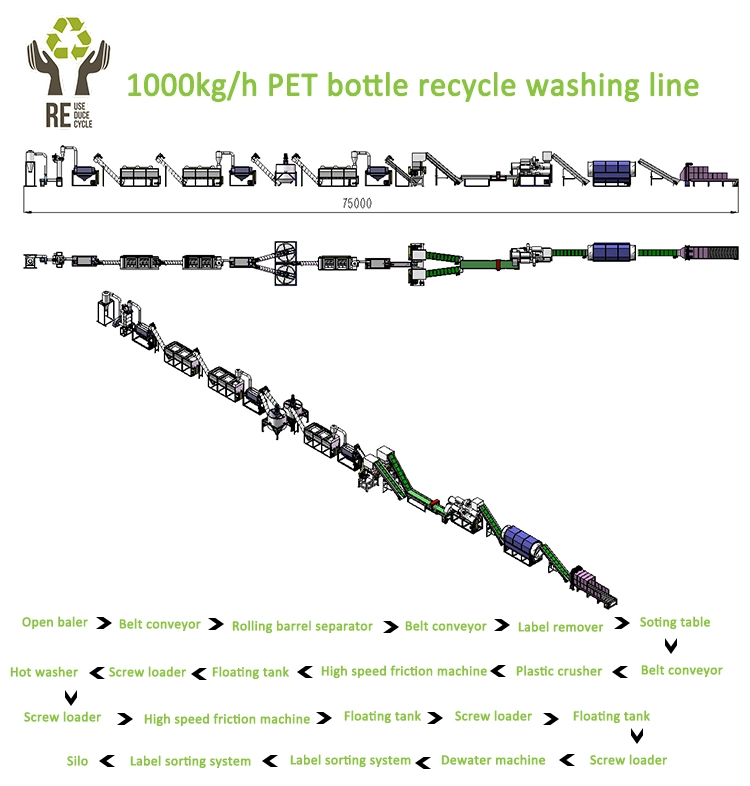

Basically the standard process for PET bottle recycling line design as below:

De-baling(bale opener)------ Label Scrapping(lable remover)-------- Persorting------Bottle Pre-washing ------ Manual Sorting and Metal Detecting-----Wet Grinding(crusher)-------Gravity Separation(floating washer)-------Chemical Washing for PET Flakes(Hot washer)-------High speed friction washer ------- Floating washing tank ------- Rinsing(clean water spraying)--------Drying--------Packing/storage hopper

Feature for PET washing line:

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 150-3000kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 or 316 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect. Here is from our customer's feedback.

Condition of final PET flake for PET washing line

Moisture: Not more than 1.0%

PVC Content: Not more than 200ppm

Metal Content: Not more than 20ppm

Label, ring and caps Content (i. e. PE, PP): Not more than 240ppm

Total amount: Not more than 560ppm

Nowadays, our PET washing line have been exported to many countries & regions, e. G. Latin-America, Mideast, Russia & MID-Asia, Africa, etc.

Prev: Waste Plastic Crusher Machine Recycling Plastic Bottle Basket HDPE Milk Bottles Crushing Machine

Our Contact

Send now